Construction In Coastal Areas With Architectural Products

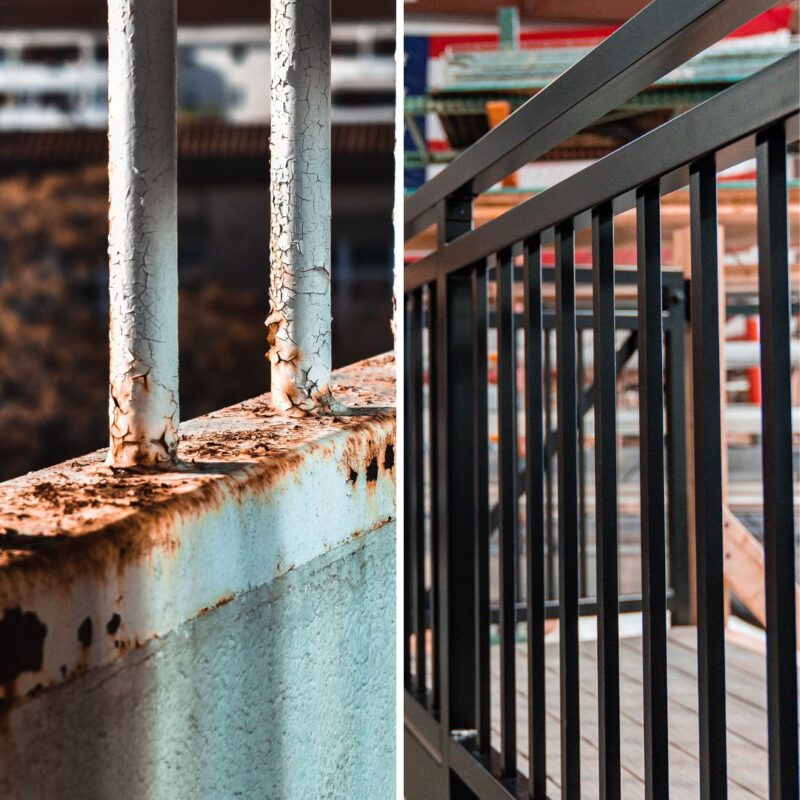

Environmental Impact on Metal Materials

Constructing in coastal areas presents unique challenges, especially due to the corrosive nature of the marine environment. Salt, humidity, and storms are prevalent, accelerating the degradation of building materials and increasing maintenance costs. For developers, architects, and contractors, choosing the right materials is crucial for ensuring long-term durability and structural integrity. Aluminum products, such as bolt-on balconies, canopies, and sunshades, offer superior resistance to corrosion, making them an ideal choice for coastal construction. This article explores the benefits of using aluminum architectural products in coastal environments, highlighting their economic, aesthetic, and environmental advantages.

Importance of Choosing the Right Materials

In coastal construction, the choice of materials is not just a matter of cost or aesthetics—it’s a fundamental decision that impacts the longevity, durability, and overall success of a project. Choosing materials that can withstand harsh marine environments without deteriorating or requiring excessive maintenance is crucial for ensuring long-term structural integrity and value.

Properties of Aluminum and Steel

Aluminum: Known for its lightweight and high strength-to-weight ratio, aluminum naturally forms a protective oxide layer when exposed to air. This oxide layer is highly resistant to corrosion, which makes aluminum an excellent choice for coastal applications.

Steel: While steel is often prized for its robustness and load-bearing capabilities, it is inherently more susceptible to corrosion unless treated with protective coatings. In coastal environments, unprotected steel can quickly begin to rust, leading to costly maintenance and potential safety risks.

Steel vs Aluminum Balcony

Comparison of Corrosion Resistance

The key advantage of aluminum in coastal environments lies in its superior corrosion resistance:

Aluminum’s Corrosion Resistance: Aluminum does not rust. Its surface is protected by a naturally occurring oxide film that is impermeable and repairs itself if damaged. This characteristic makes aluminum balconies highly durable and virtually maintenance-free in coastal settings.

Steel’s Vulnerability to Rust: Steel requires protective coatings, such as galvanization or painting, to prevent rust. In coastal areas, the salty air and moisture can quickly penetrate coatings, necessitating regular inspections and reapplications of protective layers, which adds to the upkeep costs.

Benefits of Aluminum Bolt-On Balconies For Multifamily Projects in Coastal Cities

In the debate between aluminum and steel for constructing bolt-on balconies in coastal areas, the differences in how each material responds to coastal conditions are stark. Here’s a detailed comparison focused on their properties, particularly their response to corrosion, which is a major concern in coastal environments.

Durability and Longevity

Aluminum balconies offer exceptional durability in coastal environments. Their resistance to salt and moisture prevents structural weakening over time, ensuring that the balcony remains safe and stable for years. The longevity of aluminum, coupled with its low maintenance needs, often translates into significant cost savings over the lifespan of the balcony.

Maintenance Requirements

One of the most compelling arguments for choosing aluminum over steel for bolt-on balconies in coastal areas is the reduced maintenance requirement. Aluminum balconies do not need regular painting or rust-proofing treatments. They remain aesthetically pleasing and structurally sound without the labor-intensive care that steel balconies require.

For multifamily coastal construction projects, particularly for features like bolt-on balconies, aluminum is clearly the superior choice over steel. Its natural resistance to the harsh salty environment, combined with its strength and durability, makes it an ideal material that offers long-term benefits, including lower maintenance costs, greater longevity, and enhanced aesthetic appeal. This makes aluminum not just a practical choice but a wise investment in the structural and financial health of coastal properties.

Initial Cost vs. Long-Term Savings

The choice between aluminum and steel in coastal construction isn’t just a matter of upfront costs; it encompasses a range of economic implications over the lifespan of a building project. This analysis explores the cost-effectiveness of both materials, focusing on initial expenses and long-term savings.

Initial Cost

Steel’s Lower Initial Cost:

Typically, steel tends to have a lower initial cost compared to aluminum. This makes steel an appealing option for budget-conscious projects. However, the lower upfront cost is often offset by additional expenses incurred during the life of the structure and subcontractors needed on-site.

Aluminum’s Higher Initial Price:

Aluminum generally comes at a higher initial cost. This is due to the cost of raw materials and the processing involved. Despite its higher initial price, the long-term benefits and savings associated with aluminum can justify the upfront investment.

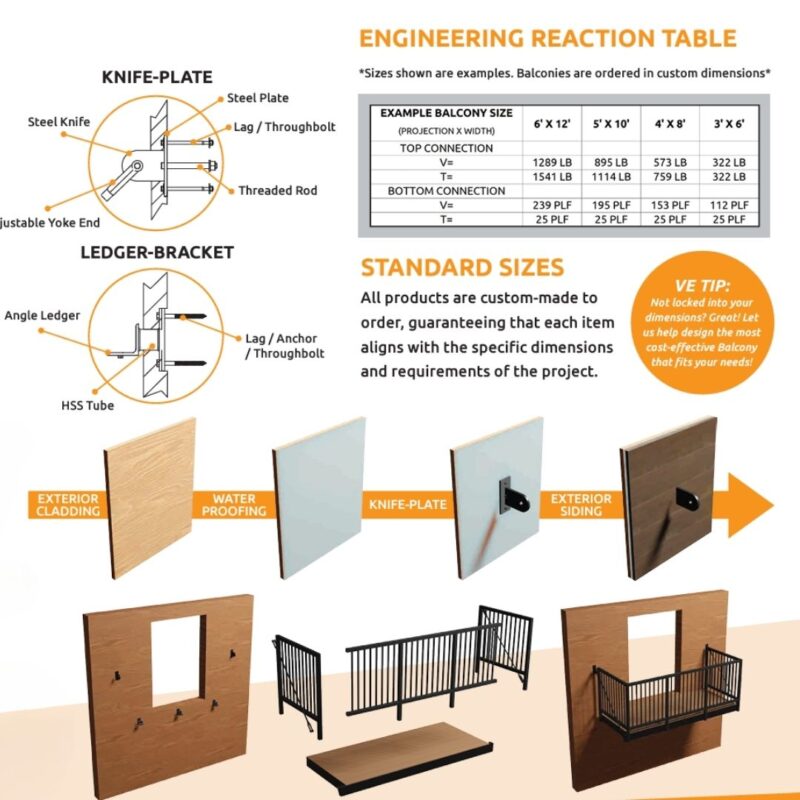

Cost Savings: Lightweight and Easy Installation

Aluminum’s lightweight nature and the design of aluminum products significantly reduce the need for skilled labor and subcontractors during installation. Unlike steel, which often requires on-site welding and specialized labor, aluminum components can be installed with minimal subcontractor involvement. This simplicity in installation is due to several key factors:

Prefabricated Designs:

Aluminum products are often prefabricated, meaning they arrive at the construction site ready for installation without the need for extensive modification or on-site welding. The lightweight properties of aluminum make it easier to handle and position, reducing the need for heavy machinery and large crews. Aluminum products are designed for straightforward assembly, often requiring only basic tools and fasteners, which simplifies the installation process and reduces labor costs.

Reducing Dependence on Subcontractors:

By choosing aluminum for construction in coastal areas, developers can mitigate the impact of the skilled labor shortage. The reduced need for specialized subcontractors not only helps in managing labor costs but also accelerates project timelines.

The ease and speed of installing aluminum products can significantly shorten construction schedules, reduce labor costs by requiring fewer skilled workers and subcontractors, and improve project management through better coordination and fewer delays. These benefits collectively enhance overall project efficiency, making aluminum an ideal choice for modern coastal construction projects.

Long-Term Savings

Maintenance Costs:

Aluminum’s natural resistance to corrosion significantly reduces the need for ongoing maintenance, repairs, and replacements. Steel, while initially cheaper, requires regular treatments to prevent corrosion, especially in coastal environments where salt spray accelerates the rusting process. These maintenance activities can add significant costs over the lifetime of a building.

Durability and Lifespan:

Aluminum structures typically last longer in harsh coastal climates compared to steel structures. The extended lifespan of aluminum reduces the frequency of major repairs or replacements, contributing to considerable savings over many years.

Impact on Property Value:

Choosing the right construction materials can also have a substantial impact on the resale value of a property. Properties featuring aluminum components, particularly in coastal areas, may benefit from higher resale values. This is due to aluminum’s aesthetic durability and lower maintenance requirements, which are highly valued by prospective buyers.

Potential Depreciation for Steel Structures:

Buildings that incorporate a lot of steel may face faster depreciation in coastal areas unless continuously maintained. The potential for increased maintenance issues and the associated costs can deter buyers, potentially affecting the property’s market value negatively.

Economic Benefits of Reduced Environmental Impact:

Aluminum not only offers direct economic benefits through durability and reduced maintenance but also contributes to lower environmental impact, which can translate into economic advantages in terms of regulatory compliance and building certifications.

Sustainability Incentives:

Using aluminum, a highly recyclable and environmentally friendly material can help projects qualify for green building certifications such as LEED (Leadership in Energy and Environmental Design). These certifications can increase a building’s marketability and value, attract tenants more quickly, and command higher rents or sale prices. With increasing regulations aimed at reducing environmental footprints, aluminum’s lower life cycle environmental impact may ease compliance with these regulations. This can prevent potential fines and reduce costs associated with environmental impact assessments and modifications.

In summary, while steel may offer an attractive lower initial cost, the long-term economic benefits of using aluminum in coastal construction often outweigh these initial savings. Aluminum’s durability, reduced maintenance needs, ease of install, and positive impact on property value present a compelling economic case for its use over steel in environments that challenge the integrity and longevity of building materials. This makes aluminum not just a cost-effective choice but a strategic investment in the future sustainability and value of coastal construction projects.

Coastal Construction with Aluminum Canopies and Sunshades

In coastal construction, the choice of materials extends beyond primary structural components to include secondary elements like sunshades and canopies. These features not only contribute to a building’s aesthetic and functional quality but also to its overall durability and maintenance needs. Aluminum, known for its robustness and low maintenance in coastal settings, is particularly well-suited for these applications. Integrating aluminum sunshades and louvered canopies can further enhance a building’s performance while maintaining a cohesive, rust-free exterior.

Benefits of Aluminum Sunshades and Louvered Canopies

Sunshades and canopies are vital in managing light and heat within a building, contributing significantly to energy efficiency and comfort. In coastal areas, these elements must withstand corrosive salty air and intense sun exposure without deteriorating.

Durability and Corrosion Resistance

Like aluminum balconies, sunshades and canopies made from aluminum offer excellent resistance to corrosion. This resistance is crucial in coastal environments where salt-laden air can quickly degrade less resilient materials. Aluminum sunshades and canopies maintain their integrity and appearance over time, free from the rust and decay that often afflict similar steel structures.

Low Maintenance

One of the most significant advantages of using aluminum for external architectural features is the reduced need for maintenance. Aluminum sunshades and canopies do not require frequent painting or rust-proofing, which is often a necessity with steel. This low-maintenance aspect is especially beneficial in hard-to-reach areas where extensive upkeep would be impractical and costly.

Consistency in Design

Using aluminum for all exterior metalwork, including bolt-on balconies, sunshades, and canopies, provides a consistent look and performance across the building’s facade. This consistency ensures that each component contributes to the overall aesthetic and functional quality of the structure, creating a seamless integration of all external elements.

Full Metal Outside Package

Adopting aluminum for sunshades, canopies, and other exterior products allows for the creation of a complete metal package that stands up to coastal conditions without the need for extensive upkeep.

Unified Aesthetic Appeal

An aluminum package offers a sleek, modern appearance that is both attractive and practical. The ability to finish aluminum in a variety of textures and colors allows architects and designers to achieve a harmonious exterior that complements the building’s design and its natural surroundings.

Enhanced Energy Efficiency

Aluminum sunshades and canopies contribute to a building’s energy efficiency by controlling direct sunlight and reducing heat gain. This control helps keep interior spaces cooler naturally, decreasing the reliance on air conditioning and reducing energy costs. The reflective properties of aluminum can also be utilized to maximize natural light, further enhancing energy efficiency.

Integrated Solutions for Coastal Challenges

Using aluminum for exterior solutions in coastal areas not only addresses the issues of durability and maintenance but also offers integrated solutions that protect against environmental challenges. Sunshades and canopies can be designed to withstand high winds and salt spray, providing both functional shading and protection from the elements.

Environmental Friendliness and LEED Certification

In addition to its practical benefits, aluminum is also an environmentally friendly choice. Aluminum is highly recyclable, reducing the environmental impact of construction projects. The use of aluminum sunshades can also contribute to achieving LEED certification by improving a building’s energy efficiency and helping to meet energy code requirements. These sunshades reduce heat gain, lower cooling costs, and enhance natural lighting, all of which are important factors in meeting LEED standards.

Conclusion: The Advantages of an Aluminum Exterior

In coastal construction, the benefits of using aluminum extend beyond individual components to encompass the entire exterior envelope. From bolt-on balconies to sunshades and canopies, aluminum provides a comprehensive solution that ensures longevity, aesthetics, and performance. With its unmatched durability, minimal maintenance requirements, and versatile design options, aluminum stands as the ideal choice for coastal properties aiming for a full metal package that withstands the test of time and nature.

Prefabricated Design Flexibility

Aluminum’s flexibility is one of its most celebrated attributes in the construction industry. It can be easily shaped, bent, and extruded into complex forms that would be difficult or impossible with more rigid materials like steel. This property allows for the creation of unique structural shapes and profiles that can transform the aesthetic and functional aspects of a building.

Prefabricated Standard Designs

Aluminum is also ideal for prefabricated standard designs that are beautiful, modern, and simple to install. These prefabricated elements streamline the construction process, reducing on-site labor and installation time while ensuring consistent quality and durability. In coastal construction, where environmental conditions demand robust solutions, prefabricated aluminum designs offer an efficient and reliable option.

Customizable Finishes, Fascias, Railings, and Colors

Like aluminum balconies, sunshades and canopies made from aluminum offer excellent resistance to corrosion. This resistance is crucial in coastal environments where salt-laden air can quickly degrade less resilient materials. Aluminum sunshades and canopies maintain their integrity and appearance over time, free from the rust and decay that often afflict similar steel structures.

Powder Coating

Powder coating offers a wide range of colors and textures, from glossy or matte finishes to effects that mimic other materials like wood or stone. This finish enhances the material’s corrosion resistance and provides a durable surface that can withstand harsh coastal conditions without fading or degrading.

Versatile Fascias and Railings

Aluminum can be formed into a variety of fascia and railing designs, providing both functional safety features and aesthetic enhancements. These elements can be tailored to match the overall architectural theme, ensuring a cohesive and visually appealing exterior.

Color Customization

Aluminum’s ability to accept various finishes allows for extensive color customization. Whether aiming for a sleek, modern appearance or a design that harmonizes with natural surroundings, aluminum can be finished in a myriad of colors to achieve the desired look. This versatility makes it an excellent choice for projects seeking a unique and personalized touch.

Reflective and Modern Appearances

Aluminum’s natural sheen lends a modern, sophisticated look to buildings. This can be particularly striking in coastal settings where the reflective quality of aluminum complements the water and sky. Architects often leverage this property to design buildings that are visually engaging and dynamic, reflecting the changing light of day and weather conditions.

Aluminum as a Catalyst for Architectural Innovation

In coastal construction, aluminum is not just a practical material choice due to its durability and maintenance advantages—it is also a catalyst for architectural innovation. Prefabricated standard designs made from aluminum offer the perfect blend of beauty, simplicity, and durability. These designs ensure high performance in marine environments while meeting the high standards of modern architectural aesthetics. By choosing aluminum, coastal projects can achieve both the robustness required to withstand harsh conditions and the elegance desired in contemporary architecture. This combination of utility and beauty makes aluminum an integral material in the future of coastal construction, enabling buildings that are both durable and artistically compelling.

Sustainability and Environmental Benefits of Aluminum in Coastal Construction

Aluminum stands out not only for its durability and aesthetic versatility but also for its substantial environmental benefits. In the context of coastal construction, where sustainability is increasingly prioritized, aluminum offers advantages that extend far beyond the immediate scope of individual projects. These eco-friendly attributes make aluminum a preferred choice for developers and architects who are committed to reducing their environmental footprint and promoting sustainable building practices.

Recyclability of Aluminum

Aluminum is also ideal for prefabricated standard designs that are beautiful, modern, and simple to install. These prefabricated elements streamline the construction process, reducing on-site labor and installation time while ensuring consistent quality and durability. In coastal construction, where environmental conditions demand robust solutions, prefabricated aluminum designs offer an efficient and reliable option.

Conservation of Resources

Like aluminum balconies, sunshades and canopies made from aluminum offer excellent resistance to corrosion. This resistance is crucial in coastal environments where salt-laden air can quickly degrade less resilient materials. Aluminum sunshades and canopies maintain their integrity and appearance over time, free from the rust and decay that often afflict similar steel structures.

Contribution to Circular Economy

The high recyclability of aluminum contributes to the circular economy, an economic system aimed at eliminating waste and the continual use of resources. Circular economy practices help create a more sustainable world by reducing the environmental impacts associated with the extraction, processing, and disposal of raw materials. Contribution to Sustainable Construction by using aluminum in construction projects supports broader sustainability goals, such as reducing energy consumption, minimizing environmental impact, and using eco-friendly materials.

Green Building Certifications

Aluminum can help construction projects achieve green building certifications such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method). These certifications often lead to various benefits, including tax incentives, reduced operating costs, and increased asset value. Buildings that incorporate aluminum are frequently recognized for their energy efficiency and sustainable design.

Energy Efficiency

Aluminum is highly reflective, which helps improve a building’s thermal efficiency by reflecting sunlight and heat. This property reduces the need for artificial cooling, thereby decreasing energy consumption and associated greenhouse gas emissions in warm climates. Furthermore, aluminum’s lightweight nature reduces energy use during transportation and installation, contributing further to its eco-friendly profile.

Lower Environmental Impact During Production

The production of aluminum, especially when utilizing recycled material, has a significantly lower environmental impact compared to many other construction materials. Advances in processing technology have continually reduced the emissions and energy consumption associated with aluminum production.

Use in Renewable Energy Projects

Aluminum is extensively used in the construction of renewable energy systems such as solar panels, wind turbines, and hydroelectric facilities. Its corrosion resistance, strength, and lightweight make it ideal for these applications, further supporting global sustainability efforts by facilitating the expansion of renewable energy infrastructure.

Aluminum’s Role in Sustainable Coastal Construction

Aluminum’s contribution to sustainable construction is multifaceted, encompassing everything from recyclability and energy efficiency to supporting renewable energy initiatives. In coastal environments, where the integrity of natural ecosystems is often at risk, choosing aluminum not only addresses the technical and aesthetic needs of construction but also aligns with broader environmental objectives. By integrating aluminum into their projects, developers, and architects can enhance their sustainability credentials while delivering buildings that are both durable and environmentally responsible.

Conclusion: The Advantages of Aluminum in Coastal Construction

Navigating the challenges of coastal construction requires innovative solutions and smart material choices. Aluminum stands out as an ideal option due to its exceptional resistance to corrosion, ease of installation, and economic benefits. With its lightweight nature and prefabricated designs, aluminum reduces the need for skilled labor and specialized subcontractors, addressing one of the industry’s most pressing issues.

For developers, architects, and contractors, aluminum products like bolt-on balconies, canopies, and sunshades not only enhance the structural integrity and aesthetic appeal of coastal buildings but also offer long-term savings and sustainability benefits. By choosing aluminum, coastal construction projects can achieve durability, efficiency, and reduced maintenance costs, ensuring that they stand the test of time and the elements.